Introduction to Extension Ladders

An extension ladder is an indispensable tool for reaching high places, whether you’re cleaning gutters, painting a wall, or repairing a roof. But with great height comes great responsibility. Choosing and using the wrong ladder can lead to accidents. This ultimate guide will walk you through everything you need to know about extension ladders, from their basic components to advanced safety techniques.

What Is an Extension Ladder?

An extension ladder is a non-self-supporting portable ladder that consists of two or more adjustable sections. These sections slide apart to extend the ladder’s length and lock into place, allowing you to access heights that fixed-length ladders cannot reach.

How Extension Ladders Differ from Other Ladders

Unlike a step ladder, which is self-supporting with an A-frame design, an extension ladder must be leaned against a stable surface. Compared to multi-purpose ladders, extension ladders are dedicated to achieving maximum vertical reach and are typically lighter and longer when fully extended.

Key Components and Terminology

- Base Section: The bottom, stationary part of the ladder.

- Fly Section(s): The upper, movable section(s) that extend upwards.

- Rungs: The horizontal steps you climb on.

- Rails: The two vertical sides of the ladder.

- Locks (or Rung Locks): The mechanisms that lock the fly section into place.

- Pulley & Rope: Used on some models to easily extend the fly section.

- Feet: The rubber or plastic caps at the bottom of the base rails for traction.

Types of Extension Ladders

1 Aluminum Extension Ladders

- Pros: Lightweight, affordable, and resistant to rust.

- Cons: Conducts electricity, making it unsafe for electrical work.

- Best For: General outdoor use where no electrical hazards are present.

2 Fiberglass Extension Ladders

- Pros: Non-conductive, making them safe for electrical work; durable and weather-resistant.

- Cons: Heavier and more expensive than aluminum.

- Best For: Electricians, utility workers, and any work near power lines.

3 Wooden Extension Ladders

- Pros: Classic, non-conductive when dry.

- Cons: Heavy, can warp or rot over time, and require more maintenance.

- Best For: Traditionalists or specific applications where other materials aren’t suitable.

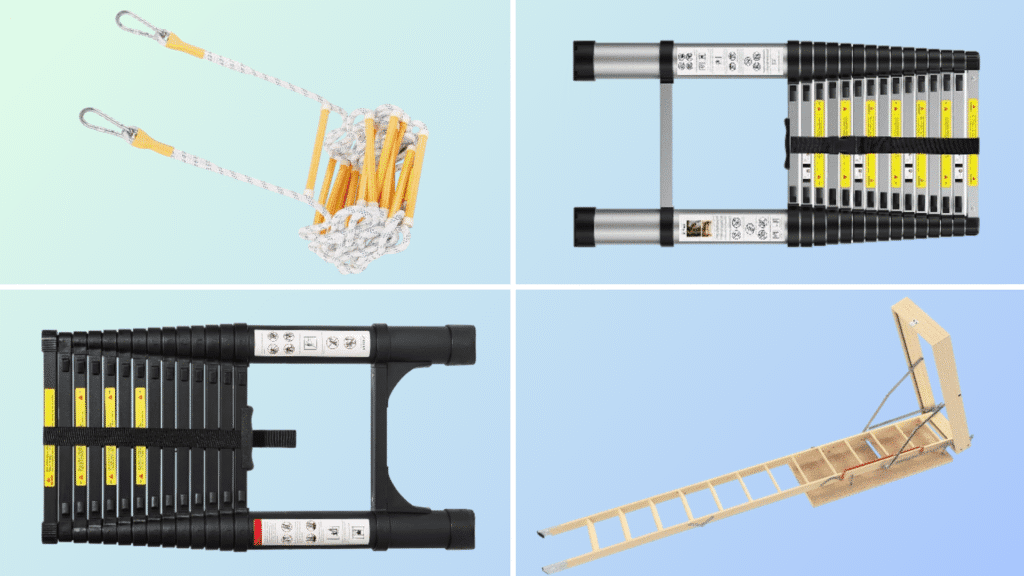

4 Telescoping Extension Ladders

- Pros: Compact and easy to store; multiple sections collapse into themselves.

- Cons: Can be less stable than standard models; mechanisms require careful maintenance.

- Best For: Users with limited storage space, like apartment dwellers or van lifers.

5 Rope & Pulley Extension Ladders

This is the most common type of extension mechanism. A rope and pulley system allows the user to extend the fly section smoothly and with less physical effort.

Extension Ladder Sizes & Height Considerations

1 Standard Height Ranges

Extension ladders are sold by their maximum extended length, typically ranging from 16 feet to 40 feet.

2 Reach Height vs. Ladder Height

Your maximum safe working height is not the ladder’s length. Due to the angle required for setup and the need not to stand on the top three rungs, a ladder’s effective “working height” is about 3 to 4 feet less than its total length.

3 Working Height Calculations

A simple rule of thumb: If you need to reach a 20-foot gutter, you will need a ladder that extends to at least 24 feet.

Materials & Construction Quality

1 Frame Materials Compared

We’ve covered the core materials (aluminum, fiberglass, wood). The key is to prioritize non-conductive fiberglass for electrical safety and lightweight aluminum for general, non-electrical tasks.

2 Locking Mechanisms & Rungs

Look for robust, easy-to-engage locking mechanisms that audibly “click” into place. Rungs should be textured or serrated to prevent slipping.

3 Weight Ratings & Duty Types

Ladders are classified by duty rating, which indicates their maximum load capacity (your weight plus tools/materials).

- Type III (Light Duty): 200 lbs

- Type II (Medium Duty): 225 lbs

- Type I (Heavy Duty): 250 lbs

- Type IA (Extra Heavy Duty): 300 lbs

- Type IAA (Special Duty): 375 lbs

4 Weather Resistance & Durability

Fiberglass is immune to rust and rot. Aluminum is rust-proof but can corrode in salty environments. Always check for corrosion-resistant hardware and robust construction.

How Extension Ladders Work

The fundamental operation involves extending the fly section(s) upwards until the desired height is reached, then engaging the locking mechanisms to secure it in place. The rope and pulley system assists in this process on traditional models.

6. Key Features to Look For

1 Slip-Resistant Rungs

Essential for safe climbing, especially in wet conditions or with dirty shoes.

2 Stabilizers & Levelers

Add-ons that increase the ladder’s contact point with the wall or ground greatly enhance stability.

3 Safety Rails

A large D-shaped bar at the top that provides a secure handhold when stepping onto a roof or platform.

4 Anti-Slip Feet

Heavy-duty rubber feet that grip the ground and prevent the ladder from sliding out.

5 Rope Quality & Operation Smoothness

A thick, durable rope that moves smoothly through the pulley is a sign of a quality ladder.

Benefits of Using Extension Ladders

- Height Versatility: One ladder can cover a wide range of heights.

- Easy Storage: They retract to roughly half their extended length.

- Multi-Use Across Industries: Essential for construction, maintenance, and home use.

- Lightweight Options Available: Aluminum models are easy for one person to transport.

Limitations of Extension Ladders

- Stability on Uneven Ground: Requires a leveler or careful setup.

- Wind & Environmental Considerations: Can be hazardous in windy conditions.

- Weight Limits: Exceeding the duty rating is extremely dangerous.

- Proper Angle Requirements: An Incorrect angle is a leading cause of accidents.

Choosing the Right Extension Ladder

1 Based on Height Requirements

Always choose a ladder that is longer than the height you need to account for the setup angle.

2 Based on Material & Weight

Choose fiberglass for electrical safety and durability; choose aluminum for light weight and affordability.

3 Based on Work Environment

Indoor work on smooth floors requires feet with excellent grip. Outdoor work on soft ground may require spike feet.

4 Choosing for Indoor vs. Outdoor Work

For indoor use, consider telescoping ladders for storage. For outdoor use, a standard rope-and-pulley model is often best.

Popular Extension Ladder Brands

1 Werner

An industry leader known for reliability and a wide range of models for pros and DIYers.

2 Louisville

Famous for their high-quality fiberglass ladders, a top choice for professionals.

3 Gorilla Ladders

Known for innovative multi-position and hybrid ladders.

4 Little Giant

The pioneer in multi-purpose telescoping ladders.

5 Local Market Alternatives

Research local brands, but ensure they meet ANSI or OSHA standards.

How to Set Up an Extension Ladder Safely

1 Correct Angle (4:1 Rule)

The bottom of the ladder should be 1 foot away from the wall for every 4 feet of height to the support point. This is the golden rule of ladder safety.

2 Securing the Base

Ensure the feet are on a firm, level surface. Have a helper hold the base or tie it off if possible.

3 Extending & Locking Sections

Fully extend the ladder and ensure all locks are securely engaged before climbing.

4 Checking Stability Before Climbing

Give the ladder a gentle shake and apply your body weight to test its stability.

Safe Climbing Techniques

1 Three-Point Contact Rule

Always maintain three points of contact with the ladder (two hands and one foot, or two feet and one hand).

2 Proper Footwear

Wear clean, dry, slip-resistant shoes. Never climb in sandals or barefoot.

3 Weight Distribution

Keep your hips within the ladder’s rails. Avoid leaning too far to either side.

4 What Not to Do While Climbing

Never carry heavy or bulky items in your hands. Use a tool belt or a hoist line.

Common Extension Ladder Mistakes to Avoid

1 Overreaching

This is the most common cause of falls. Always climb down and move the ladder.

2 Setting Up on Slippery Surfaces

Avoid wet, muddy, or icy surfaces. Use ladder levelers with large feet for soft ground.

3 Incorrect Angle Usage

An angle that is too steep can cause the ladder to tip backward; too shallow can cause the base to slide out.

4 Using Damaged Ladders

A bent rail or cracked rung compromises the ladder’s entire integrity. Do not use it.

Maintenance & Inspection

1 Pre-Use Inspection Checklist

Check for cracks, bends, loose rungs, damaged locks, and worn ropes or feet.

2 Cleaning & Lubrication

Keep rungs clean. Lightly lubricate locking mechanisms and pulleys with a dry lubricant if they become stiff.

3 Storage Best Practices

Store in a dry, cool place away from direct sunlight. Hang it horizontally or support it properly to prevent sagging.

4 When to Repair vs. Replace

Minor issues like a worn rope or foot pad can be repaired with OEM parts. Replace the entire ladder if there is any structural damage.

Extension Ladder Accessories

1 Ladder Stabilizers

A must-have for working on roofs or against siding, preventing damage and increasing stability.

2 Ladder Levelers

Adjustable legs that allow for safe setup on uneven surfaces like stairs.

3 Tool Trays & Buckets

Attach to the ladder to keep tools and materials within easy reach.

4 Protective Pads for Walls

Prevent the top of the ladder from scratching or damaging the wall surface.

Extension Ladders for Different Applications

1 Construction Use

Heavy-duty (Type IA or I) fiberglass ladders for safety and durability.

2 Home Use

A Type I or II aluminum ladder in the 24-28 foot range covers most two-story home needs.

3 Electrical & Utility Work

Fiberglass is non-negotiable. Type I or IA is standard.

4 Painting & Cleaning

A ladder with a standoff stabilizer is ideal to keep you away from the surface and prevent damage.

5 Tree Trimming & Outdoor Maintenance

Ensure the ladder is on solid ground and never lean it against a dead or unstable branch.

Extension Ladder Safety Standards

1 OSHA Regulations

The Occupational Safety and Health Administration sets legal requirements for ladder use in the workplace.

2 ANSI Ladder Classifications

The American National Standards Institute creates the performance and safety standards that most ladder manufacturers follow (e.g., ANSI A14.2 and A14.5).

3 Industry Safety Guidelines

Always follow the manufacturer’s instructions and industry best practices, like the 4:1 angle rule.

Extension Ladder vs. Other Ladder Types

1 Extension vs. Step Ladder

Use a step ladder for quick, self-supporting tasks at lower heights. Use an extension ladder for higher reaches where a stable wall is available.

2 Extension vs. Multi-Purpose Ladder

Multi-purpose ladders are versatile but often heavier and shorter when extended. Extension ladders are the specialists for maximum vertical reach.

3 Extension vs. Telescopic Ladder

Telescopic ladders are a subtype of extension ladders with a different collapsing mechanism, prioritizing storage over the raw stability of a traditional model.

Cost & Budget Considerations

1 Entry-Level Options (~$100 – $200)

Good quality Type II aluminum ladders for basic home use.

2 Mid-Range Choices (~$200 – $500)

Type I fiberglass or aluminum ladders from reputable brands like Werner or Louisville.

3 Professional & Heavy-Duty Ladders ($500+)

Type IA/IAA fiberglass ladders with advanced features for daily commercial use.

4 Cost of Accessories

Budget an extra $50 – $150 for essential accessories like stabilizers and levelers.

Buying Guide Checklist

Before you buy, confirm your ladder has:

- [ ] Height & Reach Requirements: It’s long enough for your tasks.

- [ ] Weight Capacity: It supports you and your tools.

- [ ] Material Durability: It’s the right material (fiberglass/aluminum) for your work.

- [ ] Portability & Storage: You can transport and store it safely.

- [ ] Safety Features: It includes slip-resistant rungs, secure locks, and good feet.

Conclusion

An extension ladder is a powerful tool that unlocks access to high places, but it demands respect. By choosing the right ladder for the job, inspecting it regularly, and following critical safety rules like the 4:1 angle and three-point contact, you can complete your high-elevation tasks efficiently and, most importantly, safely. Invest in quality, prioritize safety, and your extension ladder will serve you well for years to come.

FAQs

What size extension ladder do I need for a 2-story house?

For a standard two-story house, you’ll need a ladder that extends to at least 24 feet. This will safely allow you to reach gutters and eaves around 20-22 feet high.

Is fiberglass better than aluminum?

It depends on the task. Fiberglass is better for safety around electricity and is more durable. Aluminum is better for lightweight, affordability, and general non-electrical tasks. For most homeowners, aluminum is sufficient, but for professionals or anyone working near power lines, fiberglass is essential.

How often should I inspect my ladder?

Perform a quick visual inspection before every use. Conduct a more thorough inspection monthly or whenever the ladder has been dropped or damaged.

Can extension ladders be used indoors?

Yes, but with caution. Ensure the ceiling is high enough for the proper setup angle and that the floor is clean, dry, and non-slippery. The top of the ladder must rest against a sturdy surface, not drywall or a false ceiling.

What is the safest angle for setting up an extension ladder?

The safest angle is the 4:1 rule. For every 4 feet of working height, move the ladder’s base 1 foot away from the wall. An easy check is to stand with your toes touching the ladder’s feet and extend your arms straight out—your palms should just touch the rung at shoulder height.